Moulds, Keel and a Hog

This week I cut out the moulds for each station. For this I used the 1/2 inch ply I lofted the boat on, leaving the sheet with the body sections to refer to later. This process can be a bit tedious, and there are plenty of plenty of opportunities for error...in this case: measure three or four times, and cut once.

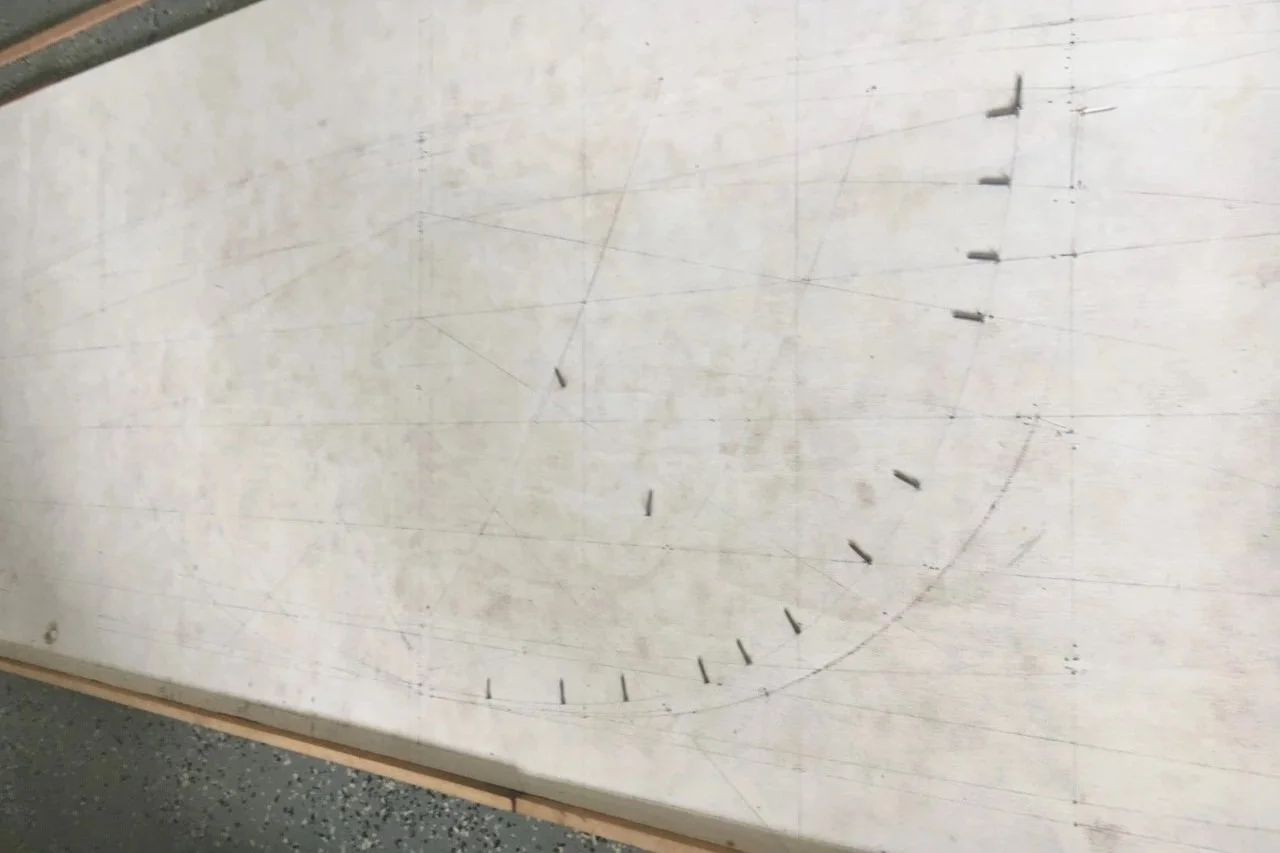

The process involves laying nails along the pencil line of the mould, then getting a piece of thin mdf the size of half the mould, and standing on the sheet so the nails imprint. From this we then hammer nails into our marks on the mdf, spring a batten around and draw a fair curve. Once we cut very carefully along this line, we have a pattern of half the mould. We then mirror this on the 12mm ply and cut it out, once again very carefully. Now we've got our mould but they it's a bit too big; we need to deduct the thickness of the planking, in this case 6.5mm. So set your marking gauge and run around the mould. Now you can make your last very careful cut and you've got a mould. One down six to go...

Theoretically, the angle of the planking in relation to the mould affects what size deduction needs to be taken. The centre mould only needs the thickness of the planking as the planks run at right angles to the mould. Whereas when the angle gets more acute near the bow, more needs to be deducted. As my boat is relatively fine in the ends the difference was no more than a millimetre. Therefore I didn't bother with the extra measuring.

I also cut out the keel and hog. The keel is made from Douglas Fir (Oregon), and the hog is of Australian Red Cedar. The keel is sawn to the rocker of the bottom.

In this photo I am chiseling out a knot in the keel timber, so I can scarph in a graving piece.